Cementing process

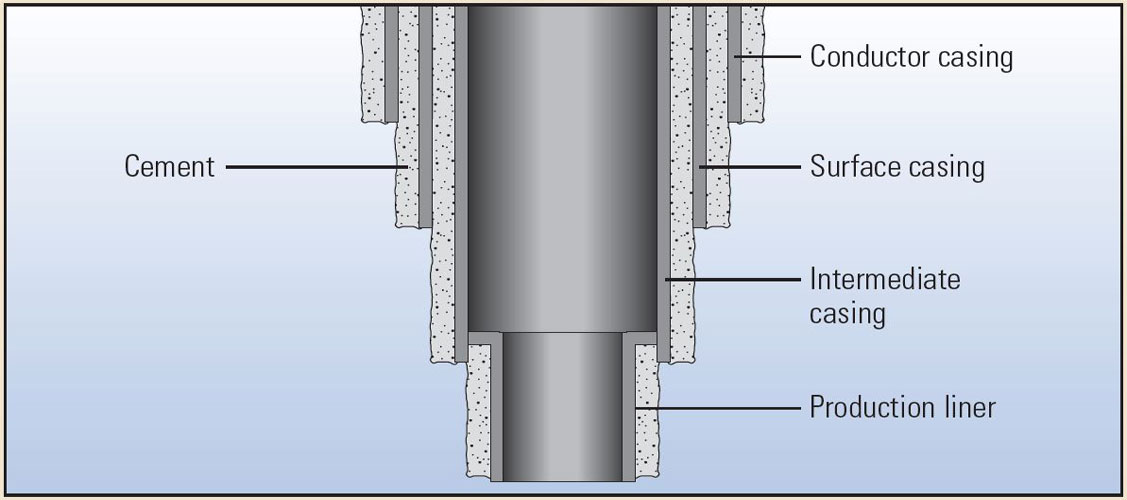

Cement is used to keep the well frame in place and to prevent fluid migration between underground formations. Cementing operations can be divided into two broad categories: primary cementing and corrective cementing.

Primary cementing

The objective of primary cementing is to provide zonal insulation. Cementing is the process of mixing a cement sludge, cement additives, water and pumping it through the outer layer to critical points (in the ring around the outer layer or in the open pit below the outer layer string). The two main functions of the cementing process are:

- Restriction of fluid movement between formations

- Binding and supporting the outer layer

If this is achieved effectively, other expectations over the life of the well will be met, including:

- Economy

- Responsibility

- Safety

- Compliance with government rules

- Restriction of fluid movement between formations

- Binding and supporting the outer layer

The position uncertainty of the well is the limit of the actual possible positions of a study station from its calculated position. It is the result of uncertainties resulting from the survey. The magnitude of the position uncertainty describes a three-dimensional ellipsoid determined by the type, quality, and pattern of uncertainty of the observation made.

Zonal isolation

Zonal isolation is not directly related to production; however, this necessary task must be performed effectively to proceed with performing production or stimulation operations. The success of a well depends on this primary operation. In addition to isolating oil, gas and water production areas, cement also helps to:

- Protecting the body from corrosion.

- Prevent bloating by quickly forming a seal.

- Protect the casing from impact loads in deeper drillings.

- Closing lost traffic areas.

Corrective cementing

Corrective cementing is usually done to correct problems related to the primary work of the cement. The most successful and economical approach to remedial cementing is to avoid it by thoroughly planning, designing and executing all drilling, primary cementing and finishing operations. The need for corrective cementing (to restore the operation of a well) indicates that the initial operational planning and execution were ineffective, resulting in costly repair operations.

Improvement cementing operations consist of two broad categories:

- Cementing by “squeezing”.

- “Outlet cementing”.

Cementing procedure

In general, five steps are needed to achieve a successful cement placement and to meet the objectives described above:

The needs of the well are determined and then fluid placement techniques are developed to meet the needs for the longevity of the well. The properties of the fluid, the mechanics and the chemistry fit the well.

The composition of the fluids (sludge) is calculated and laboratory tests are performed on the fluids designed in Step 1 to see if they meet the needs.

Calculate the volume of liquid (sludge) that will be pumped and after mixing is pumped into the ring.

Compare with step 1 and make changes as needed.

Compare with the model in Step 1 and follow up with changes as needed for future work.